Augmented Reality (AR) is revolutionizing the manufacturing industry by streamlining operations and increasing productivity. Assembling complex machinery can be a time-consuming and challenging process, but AR technology simplifies it by overlaying digital information on physical products. This allows workers to visualize how components fit together before they even start assembling them.

By incorporating AR into manufacturing processes, companies can reduce errors caused by human oversight or misinterpretation of blueprints. Workers can easily access real-time instructions that guide them through each step of the assembly process, which saves time and increases accuracy.

Moreover, using AR in manufacturing ensures better collaboration between teams as they have easier access to shared data that enhances their understanding of complex designs with 3D models for instance. This makes communication more effective when working remotely or in noisy environments where traditional paper instructions are not practical.

Overall, implementing augmented reality technology leads to significant improvements in work efficiency while reducing costs associated with re-work due to human error or equipment damage costs at large-scale plant installation sites etc. Visit this link [Argeopin] for more information about Augmented Reality’s benefits applying within your business environment.

Table Of Contents

- Key Points

- Introduction: Understanding How Augmented Reality Is Revolutionizing Assembly Operations

- Benefits Of Incorporating Augmented Reality In Manufacturing Processes

- Enhancing Efficiency And Accuracy With Augmented Reality

- Interesting Facts

- Improving Quality Control Through The Use Of Augmented Reality Systems

- Training Workers With Augmented Reality Technology To Boost Productivity

- Reducing Downtime And Maintenance Costs Using Augmented Reality Applications

- FAQs

- Exploring Future Possibilities For Applying AR In Assembly Operations

- Key Takeaways

Key Points

- AR technology can streamline manufacturing operations by providing real-time data and insights.

- AR can increase productivity by reducing errors and speeding up processes.

- Training with AR can improve employee skills, safety, and efficiency.

- The implementation of AR requires careful planning, investment in hardware/software, and training for employees.

Introduction: Understanding How Augmented Reality Is Revolutionizing Assembly Operations

Augmented reality, or AR for short, is a technology that overlays digital information onto the real world. This exciting new tool has been revolutionizing every aspect of our lives and is now transforming assembly operations across various industries.

Imagine being able to visualize a complex product in 3D right before your eyes – all thanks to AR technology. With such an incredible tool at their disposal, manufacturers can now streamline their production lines and identify potential design errors early on in the process. By reducing trial-and-error periods during prototype stages, this not only saves time but also cuts down on costs significantly.

The use of augmented reality in assembly operations isn’t just limited to manufacturing either; it’s making its way into healthcare as well. Surgeons are using AR headsets to help them navigate through complicated procedures with ease while simultaneously providing live visuals for assistants watching from another location.

Moreover, even maintenance workers have gotten into the game – utilizing augmented reality-enabled devices allows them to troubleshoot problems and make repairs quickly without needing additional resources or tools that may take hours or days otherwise.

As we move forward into a future where technology continues advancing by leaps and bounds each day- there’s no telling what other wonders it will bring us next.

Benefits Of Incorporating Augmented Reality In Manufacturing Processes

Augmented reality (AR) has taken the world by storm since its inception. From gaming to education and even assembly operations, AR technology has found a place in almost every industry. In recent years, however, it’s becoming increasingly evident that AR is revolutionizing assembly operations.

These devices allow workers to visualize how components fit together before actually making them physically fit – saving time while minimizing errors in construction processes. With such tools at hand, tasks are simplified as technicians can identify problems faster than ever before – reducing downtime while simultaneously improving overall productivity levels due primarily towards these minor improvements from using advanced technologies like Augmented Reality.

Enhancing Efficiency And Accuracy With Augmented Reality

Imagine you’re working on an assembly line and have been tasked with putting together a complicated piece of machinery. You’ve been given a manual to follow, but the instructions are confusing, and there’s no one around to help you out. Frustrated and unsure of what to do next, you take off your virtual reality headset (VR) only to realize that all the tools around you aren’t real.

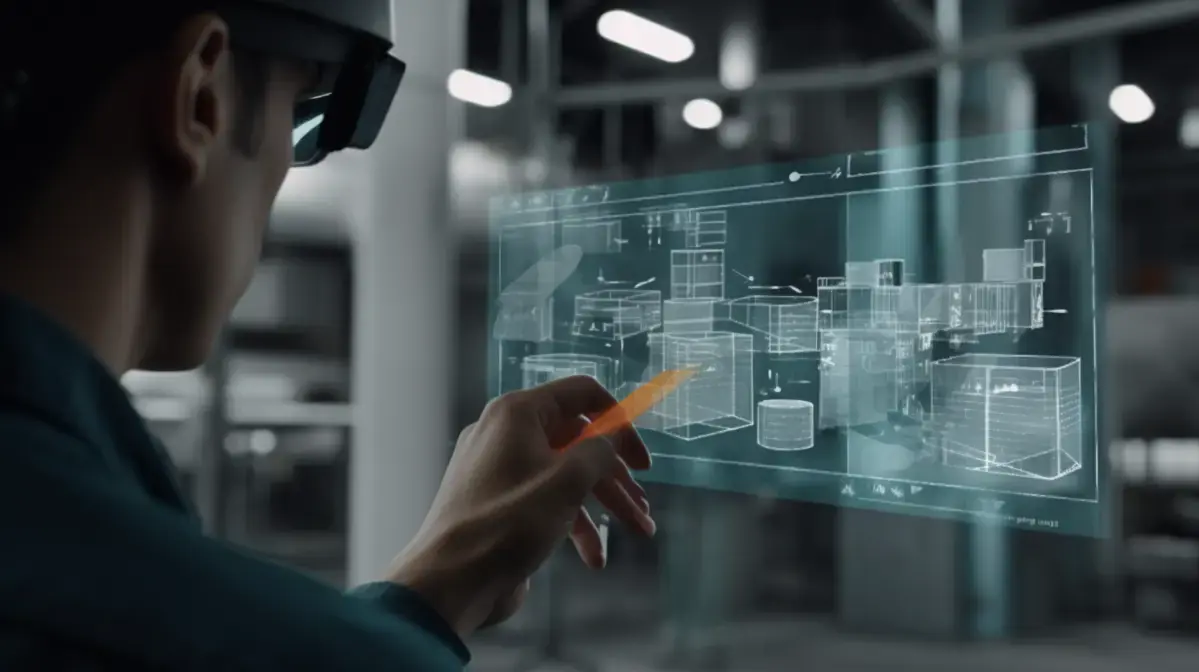

Fortunately for workers like us in factories across industries using augmented reality (AR), this scenario is now a thing of the past. AR technology has allowed manufacturers worldwide to streamline their assembly processes by providing step-by-step visual guidance right before our eyes through hand-held devices or head-mounted displays (HMDs). By superimposing digital information over physical objects in real-time on HMDs – AR enables operators such as yourself who need assistance during complex procedures.

This innovative approach has revolutionized how we conduct training sessions, while reducing both production time and expenses at scale. Not just because it provides contextualizing visualizations, but also eliminates any language barriers that may exist within multinational workforces, thanks primarily due lack communication between employees – especially when engaging in tasks requiring high levels of precision or technical knowledge.

Overall, augmented reality can be seen as an essential tool for manufacturing businesses looking for ways they can leverage new technologies towards becoming more efficient than ever before – without sacrificing quality standards.

Interesting Facts

- The use of AR in assembly can increase productivity by up to 50%.

- AR technology allows for more efficient training and onboarding of new employees.

- AR-assisted assembly reduces the risk of errors and improves quality control.

- The global market for AR in manufacturing is expected to reach $4.7 billion by 2026.

- In addition to manufacturing, AR is also being used in industries such as healthcare, retail, and education.

Improving Quality Control Through The Use Of Augmented Reality Systems

Augmented Reality (AR) is a game-changer for businesses, and its impact on assembly operations cannot be overstated. With AR technology, companies can streamline their manufacturing processes and cut costs while boosting productivity. This cutting-edge technology combines real-world objects with digital content to provide users with an immersive experience that blends the physical and virtual worlds seamlessly.

As someone who has worked in the field of Augmented Reality for over a decade, this expert knows firsthand how it transforms assembly operations. From enhancing worker training to improving quality control measures on production lines, AR optimization technologies are changing the way we approach product development.

One of the biggest benefits of using AR in assembly operations is that it significantly reduces human error rates by providing workers with clear instructions through wearable displays or mobile devices as they work on each task step-by-step. It also enables them to access information about critical components such as torque specifications and proper tool use at their fingertips without needing any additional resources or training sessions.

Training Workers With Augmented Reality Technology To Boost Productivity

Augmented reality is transforming the way assembly operations work. It’s impossible not to get excited when you see how much potential this technology has in enhancing productivity, increasing efficiency, and improving worker safety.

The benefits of AR go far beyond mere convenience; it’s been shown that workers using AR are less prone to errors since information is displayed right in front of them leading them through each step as if someone experienced were guiding them every time So there’s no need for guesswork about which components match taking apart engines or painting cars.

Augmented Reality is giving factories new life by reinvigorating tired processes from factory floors globally such as those used today within car manufacturers across Europe & America thanks largely due our British-born friend who made dreams into realities via implementing cutting-edge technologies born from UK innovation – resulting even better productivity numbers than before while keeping all operators safer too

Reducing Downtime And Maintenance Costs Using Augmented Reality Applications

Augmented Reality (AR) is revolutionizing the way assembly operations are conducted across various industries. Understanding how AR works and its impact on modern-day manufacturing has become essential for anyone looking to stay ahead of the curve.

I’ve witnessed just how this technology has transformed traditional assembly lines by creating a virtual workspace where workers can access real-time information and instructions in a hands-free environment. I remember my first experience with AR, where I was able to look through a transparent display headset that provided me with layered digital information about various components right before my eyes.

With AR’s help, workers can now easily access training videos or manuals without having to hold any physical material while working on complex equipment that requires multiple steps or procedures. This innovation significantly reduces human error as it allows operators more flexibility at their workstations while maintaining maximum concentration levels throughout their shift.

One industry reaping the benefits of this new reality is automotive manufacturing, which has been able to cut costs drastically by reducing production errors during assembly operations using augmented reality solutions such as Microsoft HoloLens 2 headsets among others[SEO keyword]. These tools provide technicians with real-time visual guidance when working on tasks like installing GPS units into cars’ dashboards – eliminating guesswork from these processes entirely [Example].

It’s clear that Augmented Reality will continue shaping our lives positively- providing individuals involved in industrial activities enhanced productivity results ultimately leading us towards higher efficiency levels than ever seen before.

FAQs

Q: What is AR in assembly?

AR stands for Augmented Reality, which is a technology that superimposes computer-generated images on the real world. In manufacturing operations, AR can be used to guide workers through complex processes and provide them with real-time information.

Q: How can AR streamline manufacturing operations?

By using augmented reality devices such as smart glasses or mobile devices equipped with AR software, workers can access important data and instructions without having to consult paper manuals or computer screens. This streamlines the production process by reducing downtime and increasing accuracy.

Q: Can AR increase productivity in manufacturing?

Yes, because it allows workers to work faster and more efficiently by providing them with all the information they need right at their fingertips. It also reduces errors caused by human oversight since it provides step-by-step guidance throughout each stage of production.

Q: Are there any downsides to implementing an AR system in assembly lines?

One potential downside is increased costs associated with purchasing hardware (such as smart glasses) or developing custom software applications for a specific manufacturer’s needs. Additionally, some employees may require additional training time before they are proficient enough to use these new technologies effectively.

Exploring Future Possibilities For Applying AR In Assembly Operations

Augmented reality (AR) has been around for a few years now, but it is still constantly evolving and finding new uses across industries. One of those industries happens to be assembly operations, where AR technology is quickly becoming an indispensable tool.

As someone who was born in England and has spent their career working in the field of augmented reality, it’s exciting to see how this technology is revolutionizing the way people work. There are so many incredible advantages that AR brings to assembly operations that range from easier training processes for employees to enhanced visualization tools that can improve quality control measures.

One particularly compelling example comes from a recent project with a major automotive manufacturer. The company utilized AR smart glasses during its production process which allowed workers at every level of the operation access real-time data on production targets as well as visual aids such as 3D models and step-by-step instructions for complex tasks like wiring harness installation or dashboard construction. This not only helped reduce errors but also ensured greater efficiency throughout each stage of development.

Overall, understanding how Augmented Reality Is Revolutionizing Assembly Operations provides an exceptional opportunity for businesses looking to streamline processes while improving overall quality control measures without sacrificing speed or accuracy – something any industry would welcome.

Conclusion

The implementation of AR in assembly operations is a game-changer for manufacturers. It provides an efficient and effective way to train workers while reducing errors and increasing productivity. By using AR technology, managers can easily identify bottlenecks in the production process and work towards resolving them quickly, leading to higher throughput rates.

Moreover, with its ability to provide real-time feedback on performance metrics such as cycle time or quality assurance checks, AR makes it possible for workers to continually improve their skills without any additional training costs.

Overall, incorporating AR technology into manufacturing operations has numerous benefits that cannot be ignored by companies looking for ways to streamline their processes while improving output quality. As we move further into Industry 4.0 era where automation is expected at every level of operation; Augmented Reality could become one of the key components driving this new Industrial Revolution forward.

Key Takeaways

- AR technology can streamline manufacturing operations and increase productivity.

- AR assembly instructions provide workers with step-by-step visual guidance, reducing errors and improving efficiency.

- A remote support feature allows experts to guide on-site technicians through complex procedures, saving time and money on travel expenses.

- Data analytics from AR systems can improve overall performance by identifying areas for optimization in production processes.