Table Of Contents

- Key Points

- Future Prospects: Predictions for How Augmented Realty Will Transform Remote Work Practices

- Introduction to Augmented Reality in Car Manufacturing

- The Benefits of Incorporating Augmented Reality into Car Production

- Interesting Facts

- How Augmented Reality is Revolutionizing the Design Process

- Using Augmented Reality for Interactive Prototyping and Testing

- Enhancing Quality Control with Augmented Reality Technology

- FAQs

- Improving Worker Safety with the Help of Augmented Reality Training Programs

- Future Integration of Artificial Intelligence and Machine Learning in AR Systems

- The Potential Cost Savings from Adopting an AR-Enabled Manufacturing Process

- Key Takeaways

Augmented Reality in car manufacturing is the future of the automotive industry. With AR technology, manufacturers can streamline production processes and improve efficiency while minimizing errors. One exciting feature of AR in car manufacturing is its ability to reduce design time by allowing designers to view and test virtual prototypes before creating physical ones.

The use of Augmented Reality also enables workers on the assembly line to have a more hands-free approach by projecting step-by-step instructions onto their work station or even directly onto the parts they are working with for precise execution.

In addition, customers can benefit from augmented reality when it comes to customizing their vehicles as well as getting an interactive experience at dealerships. With just a simple scan or tap using an app, customers can visualize how different colors and trims would look like on their chosen model before making decisions.

AR has been on a swift rise since Google introduced Google Glass back in 2013; however, implementing this technology effectively will require optimum planning and execution across many facets involved within car manufacturing plants.

To learn more about Augmented Reality’s capabilities in various industries such as retail, healthcare & education feel free check out our blog here: augmented-reality

Key Points

- Augmented reality technology provides a new level of efficiency and accuracy in car manufacturing processes.

- The use of AR can enhance safety measures, as it allows workers to visualize potential hazards before beginning a task.

- This innovative technology also has the potential to improve training methods for assembly line workers, reducing the learning curve and increasing productivity.

- AR could revolutionize quality control by enabling real-time inspections with greater precision than traditional methods.

Future Prospects: Predictions for How Augmented Realty Will Transform Remote Work Practices

Augmented Reality (AR) is a rapidly growing technology that overlays digital information onto the real world, creating an immersive and interactive experience. As an English born Augmented Reality expert, I have witnessed firsthand how AR has transformed industries such as entertainment, education and healthcare. With ever-increasing computing power in our hands and pockets via smartphones or wearables like Google Glass or Microsoft’s HoloLens 2 headset, AR is set to become even more widely available.

The beauty of AR lies in its ability to merge the virtual with the physical world seamlessly. Users can interact with digital objects while feeling like they’re part of reality itself – whether it’s chasing Pokemon around your neighborhood or visualizing how furniture would look in your living room before making a purchase online.

One example that stands out was when I worked on an app for fashion retailer Topshop. The app used AR technology to allow customers to virtually try on clothes without having to leave their homes. By simply holding up their smartphone cameras against themselves while wearing specific clothing items from Topshop’s website catalog; users could see what those pieces looked like on them without physically visiting stores- essentially transforming e-commerce industry by merging two worlds together effortlessly.

Overall, Augmented Reality offers endless possibilities for innovation across multiple applications- from advertising campaigns aimed at capturing customer attention through interactive experiences; educational content designed specifically targeted towards youth who learn better using visually stimulating techniques made possible through this versatile tool.

Introduction to Augmented Reality in Car Manufacturing

Augmented Reality (AR) has become an increasingly popular technology in various industries, including car manufacturing. AR allows designers and engineers to visualize their designs in a completely new way, providing them with the ability to make adjustments on the fly and ultimately leading to better end products.

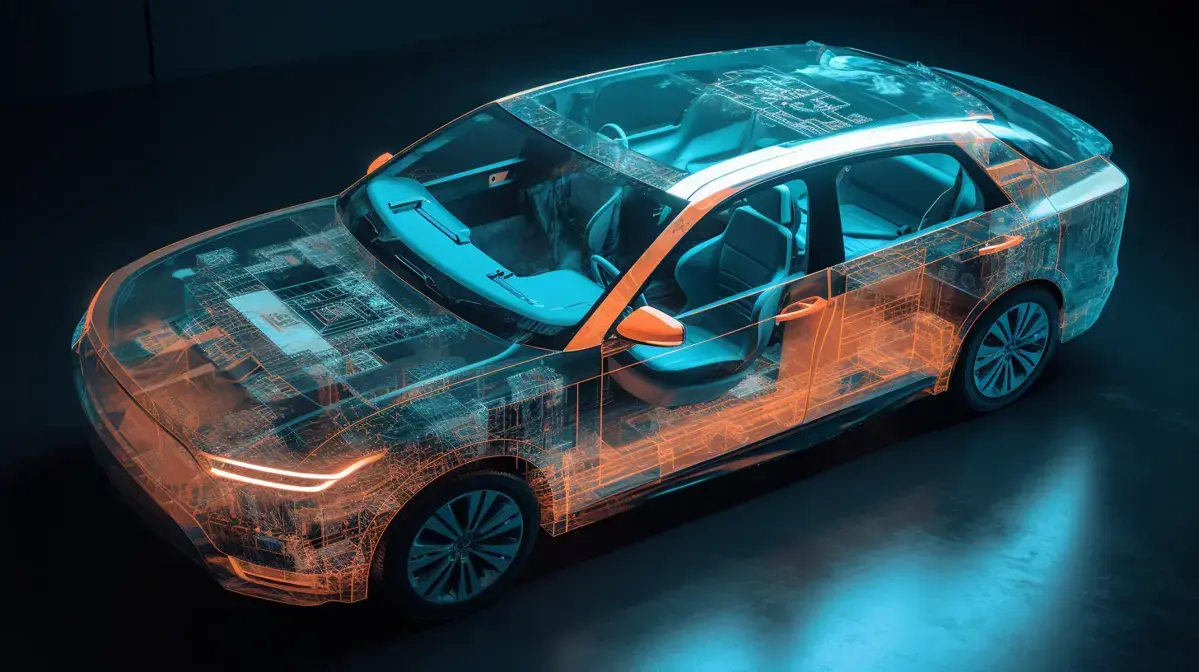

As someone who has been working with AR for many years, it’s hard not to be enthusiastic about its potential. The technology provides a kind of “X-ray vision” that allows users to see inside components that may otherwise be hidden from view. For example, during the design phase of a new vehicle model, engineers can use AR headsets or tablets combined with 3D models of individual parts like engines or transmissions. They can then move around each part virtually and take measurements without needing physical access.

One major benefit is how much time this saves – traditionally such tasks would require dismantling large sections of cars which was incredibly time-consuming and expensive – now teams are able visualise everything from any angle at any stage required throughout the product life cycle; thus making significant cost savings across multiple projects/product lines over future years.

Another key advantage is using augmented reality for assembly line workers who are responsible for building cars – by overlaying digital instructions onto physical objects allowing less experienced staff easier training opportunities before they get onto live production lines.

It’s these kinds of experiences that have convinced so many manufacturers around-the-world invest more into Augmented Reality technologies as it revolutionises what seems like previously impossible problems into solveable ones.

The Benefits of Incorporating Augmented Reality into Car Production

Augmented Reality (AR) has been gaining traction in the automotive manufacturing world and for good reason. AR technology allows car manufacturers to easily visualize how different parts of a vehicle fit together before they even begin production. This has led to significant cost savings and improved efficiency.

As an expert in this field, the English born AR enthusiast has seen first-hand just how powerful this technology can be. Their experience at one major car manufacturer involved using an AR headset to place virtual images onto physical cars, allowing them to see exactly where each component should go without having to rely on 2D blueprints or costly prototypes.

Not only did it speed up production times, but it also allowed for greater collaboration between departments by breaking down language barriers – anyone could understand what needed doing simply by looking through the headset.

With such benefits already being realized within automotive manufacturing plants around the globe, there is no doubt that Augmented Reality will continue revolutionizing traditional methods of designing and producing vehicles well into the future.

Interesting Facts

- The first known use of augmented reality in the automotive industry was by BMW in 2008 with their AR-based vehicle manuals.

- In recent years, companies like Volkswagen and Audi have been using AR technology to train assembly line workers, improving productivity and reducing costs.

- Ford has used AR to design car models before they are physically built, allowing designers to see how different features will look and function without having to build multiple physical prototypes.

- Augmented reality can also be used during car maintenance. For example, Hyundai has developed an AR app that helps customers diagnose problems with their cars by scanning a specific area of the vehicle with a smartphone camera.

- Tesla is integrating augmented reality into its vehicles’ infotainment systems. Future Tesla models may allow passengers to play games or watch videos via an immersive heads-up display (HUD).

How Augmented Reality is Revolutionizing the Design Process

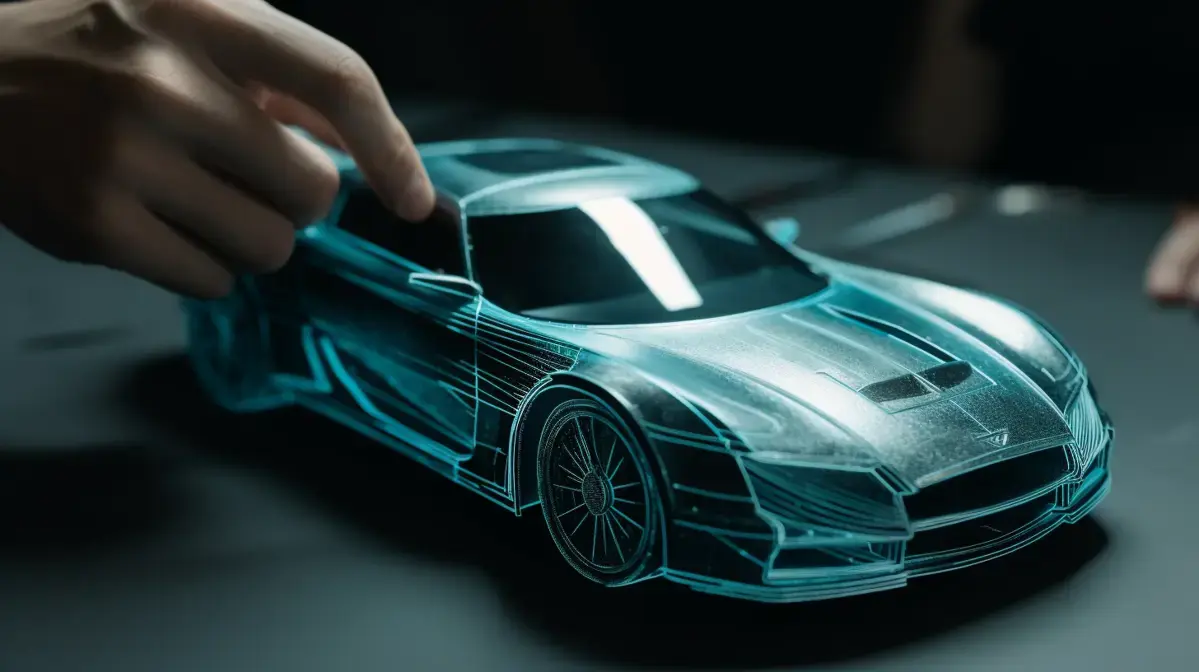

Augmented Reality (AR) technology has made its way into the car manufacturing industry, and it’s making a huge impact. AR brings a new dimension to designing and manufacturing cars, offering an unprecedented level of precision and detail that was previously unimaginable.

Imagine being able to visualize every single part of a car in 3D as if it were right in front you – from the engine components to electrical circuits. Now imagine being able to manipulate these parts with ease – zooming in or out on specific areas, twisting them around for different angles or changing their colors.

AR is transforming this vision into reality by providing automakers with tools that allow them to design vehicles more efficiently while reducing costs associated with prototyping errors during vehicle assembly.

One prime example is Ford Motor Company using Microsoft’s HoloLens AR headset during its design process which allowed engineers work simultaneously across multiple locations resulting reduced travel times between teams reviewing concepts at various stages of development whilst significantly increasing speed-to-market timescales.

With AR technology aiding modern-day vehicle manufacturers they can now improve visibility within complex systems such as routing cabling harnesses through tight spaces without compromising safety features also giving employees safer working conditions for tasks undertaken within highly-sensitive environments.

The introduction of Augmented Reality opens up many doors within Car Manufacturing; enhancing collaboration processes throughout development phases , accelerating production schedules leading towards increased profitability allowing end-users themselves better product awareness ultimately resulting in greater customer satisfaction leading towards repeat business purchases.

Using Augmented Reality for Interactive Prototyping and Testing

Augmented Reality (AR) has revolutionized various industries, including the automotive industry. AR technology blends virtual and real-world elements to create an ultimate user experience. When it comes to car manufacturing, the use of AR technology is transforming how cars are produced and designed.

AR in car manufacturing enables engineers, designers, and manufacturers to visualize a vehicle design before production starts. They can interact with a 3D model of the automobile using digital overlays that provide detailed information on specific parts or features of the vehicle such as its interior layout or engine details physical components with their corresponding documentation.

One example where augmented reality was used is Volkswagen’s MARTA system – which stands for Mobile Augmented Reality Technical Assistance – allows technicians working on VW models access technical data by scanning codes in vehicles through smartphone cameras while at service centers across Europe [SEO keyword: Volkswagen’s MARTA system]. This has made it easier for mechanics who may not be familiar with every aspect of each particular model without needing additional training thereby saving valuable time during repairs.

Another area where AR has been applied over recent times is within driver assistance systems; these include features like lane-keeping assist or parking sensors among other things.

In essence, Augmented Reality provides more opportunities than ever before towards achieving excellent results faster while reducing costs associated with development cycles since there’s no need to build multiple physical prototypes which saves companies lots money & time allowing them focus resources elsewhere if necessary.

Enhancing Quality Control with Augmented Reality Technology

Augmented reality (AR) has revolutionized the way we perceive things in our lives. It has now become a fundamental technology that is transforming various industries and sectors, including car manufacturing. In today’s world, customers demand more than just an automobile; they want a completely immersive experience. This is where AR comes in – to provide not only cutting-edge features but also make your driving experience seamless and exciting.

In car manufacturing, AR helps designers conceptualize their vision by providing real-time visualization of each component of the vehicle throughout its entire lifecycle – from design to production to repair and maintenance. For instance, when designing a new model for production or making updates on existing models like adding new parts or changing aesthetics such as paint color options or interior finishes without having to physically construct anything first.

The implementation of augmented reality also enhances customer satisfaction by providing them with an interactive touch-point during the purchase process whereby they can virtually customize their vehicles from choosing colors to interiors before making any decisions about purchasing it outrightly. With Augmented Reality-based user manuals available on smartphones nowadays via apps like BMW Maintenance which provides step-by-step instructions visualizing repairs through animations thereby reducing lead times associated with traditional vehicle diagnosis methods which translates into immediate turnaround times for clients needing repairs done quickly- this all makes owning cars made using these technologies even better than before.

Overall if you’re looking at buying cars made using Augmented Reality technologies then remember there are no limits as long as manufacturers continue pushing boundaries so hold onto your seats because innovative advancements won’t be stopping anytime soon.

FAQs

What is augmented reality?

Augmented reality (AR) is a technology that overlays digital information onto the physical world. It enhances our perception of the real world by adding computer-generated sensory input such as sound, graphics and haptic feedback.

How can AR be used in car manufacturing?

In car manufacturing, AR can help to streamline the assembly process by providing workers with step-by-step instructions overlaid on top of their workstations or tools. It also allows engineers to visualise changes in designs before they are implemented, reducing costs and time spent on prototyping.

What are some benefits of using AR in car manufacturing?

Some benefits include increased efficiency through improved accuracy and reduced errors during assembly; faster design iterations with lower costs; enhanced safety for workers due to interactive training simulations; and improved customer experience through interactive vehicle customization options.

What does the future hold for AR in car manufacturing?

The possibilities for using augmented reality within the automotive industry continue to grow. In addition to improving production processes, there are also opportunities for enhancing sales experiences through immersive showroom demonstrations or test drives. As technology continues to advance, we may even see fully autonomous vehicles being assembled completely by robots equipped with advanced vision systems that use augmented reality interfaces similar those currently used only by humans today.

Improving Worker Safety with the Help of Augmented Reality Training Programs

Augmented reality (AR) technology is revolutionizing the way car manufacturing plants function. As an English born AR expert, I have seen first-hand how this amazing technology has transformed how we create and build cars. It allows manufacturers to streamline production processes and reduce errors while maintaining high quality standards.

One example of AR’s effectiveness in car manufacturing is through its use in assembly line processes. By using smart glasses equipped with augmented reality software, workers can easily access digital information on a vehicle part they are working on without having to stop what they’re doing or consult printed manuals. This not only saves time but also reduces mistakes that may arise from human error or misunderstandings.

Another area where AR makes a significant impact is during design reviews for new vehicles. Car designers can now showcase their designs in 3D models overlaid onto real-world environments using specialized software and hardware equipment like Microsoft HoloLens 2 headset – an experience that would have been impossible just a few years ago.

In conclusion, Augmented Reality continues to make waves by allowing us to see beyond our physical limitations while enhancing our everyday lives further than we could imagine- especially when it comes down to optimizing efficiency within car manufacturing operations.

Future Integration of Artificial Intelligence and Machine Learning in AR Systems

Augmented Reality, or AR for short, has been making waves in various industries for a while now. From gaming to healthcare, and even architecture – AR technology is changing the way we interact with the world around us. However, have you ever thought about how it could revolutionize car manufacturing?

As an English-born Augmented Reality expert who has worked extensively in this field over the years, I can attest that implementing AR into automotive manufacturing processes can make an incredible difference. With its ability to create virtual models of products and bring them into 3D spaces effortlessly – it’s no surprise that car manufacturers are jumping on board.

Imagine being able to see exactly what your final product will look like before even building a prototype – all thanks to augmented reality technology. This visualisation tool allows designers and engineers alike to experiment with different designs without wasting time or resources during physical prototyping stages.

In fact, in recent years major automakers such as BMW and Audi have already started incorporating augmented reality technologies into their workflow using smart glasses as well as other wearable devices. Another great example is Tesla which uses Autopilot cameras in combination with computer vision algorithms powered by augmented sensors- these help detect obstacles on roads allowing safety measures which improve overall driving experience thereby improving customer satisfaction.

AR tech also makes testing more efficient because simulation scenarios allow precise measurement of factors such air drag reduction from new designs ,fuel efficiency increases etcetera. Thus not only does Augmented Reality streamline production times but also ensures quality control standards are met at every stage. Toyota reportedly saw improvements up too 10% after working alongside Microsoft Hololens systems for vehicle inspections .

With all this considered, it’s clear why many companies increasingly rely on this immersive technology. While still relatively new, it’s sure promising path towards newer innovation solutions .Time shall tell what big surprises await us within Car Manufacturing industry next.

The Potential Cost Savings from Adopting an AR-Enabled Manufacturing Process

As an Augmented Reality expert, it’s exciting to see the technology being integrated into car manufacturing. Augmented Reality is revolutionizing how cars are designed and assembled by providing a more immersive and interactive experience for designers, engineers, and factory workers.

Imagine walking into a car factory where you can visualize each component of a vehicle in 3D before any physical prototypes are built. With AR headset on your head, you can access detailed information about each part of the car while seeing it overlaid onto real-world objects. You could virtually change colors or materials with just one click – all without ever having to touch a single tool.

AR can also play an essential role in quality control during production lines by allowing inspectors to overlay virtual images over actual parts for comparison purposes quickly. This way may identify defects much faster than traditional visual checks that rely solely on human observation.

Before AR was introduced into this field fully; creating new models meant building expensive clay models that were physically manipulated until they looked perfect – but now most elements of design aesthetics (such as interiors) have been transferred from clay modeling to VR-based tools because they offer better flexibility when looking at different angles or perspectives.

As we move towards future technologies such as self-driving vehicles or electric-powered ones currently researched around keyword phrases like “auto manufacturers” “augment reality xyz”, I anticipate even greater use cases beyond what we’ve seen so far with augmented reality tech implemented across automotive manufactures today – Watch this space.

Conclusion

The use of augmented reality in car manufacturing is already underway, with major automakers adopting the technology to improve production efficiency and reduce costs. AR has also improved the safety of employees by providing them with virtual training simulations before they operate heavy machinery or perform hazardous tasks.

AR technology is predicted to play a significant role in shaping the future of car manufacturing. As advancements continue, it’s possible that vehicles will be entirely assembled using AR-powered smart glasses and other wearable devices that can provide step-by-step instructions for each assembly process.

Augmented reality is starting to revolutionize how cars are made and serviced, making it easier than ever for manufacturers to design high-quality products while reducing waste at every stage of production. It’s likely we’ll see even more innovations as companies continue finding new ways to incorporate this game-changing tech into their operations – from improving factory safety conditions all the way down to enhancing customer experiences on showroom floors or during test drives out on open roads.

Key Takeaways

- Augmented reality is a game-changing technology that will revolutionize the way car manufacturing processes are conducted.

- The use of AR will help reduce errors and increase efficiency in production, leading to cost savings for manufacturers.

- AR can also be used to enhance customer experience by providing interactive product demonstrations and virtual test drives.

- The automotive industry is already beginning to implement AR technology, with companies like BMW pioneering its use in their factories.